S-Type Single Wall Corrugated Sheets

Request a quote today and let our team provide you with the pricing for a comprehensive solution for your specific needs

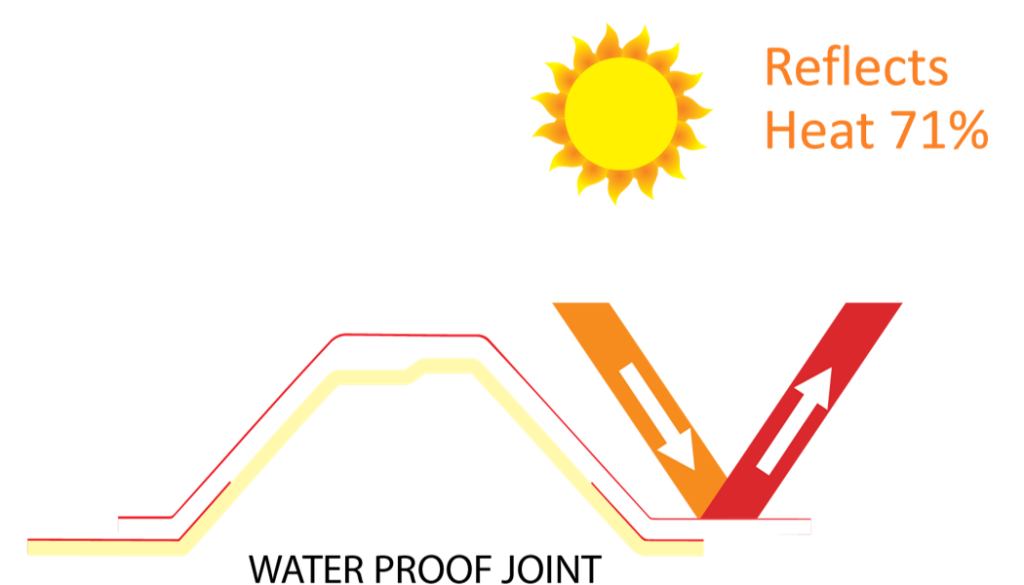

Male & Female Joint

Overview

- Cost effective & maintenance free

- Abrasion resistant and variety of color options

- Light weight & Alternate of Inferior metal roofing system

- Good mechanical strength & impact resistant

- Can be cut, shaped, welded and jointed

- Environment friendly & Easy to install

Production Process

1. Introduction of polymer compounds and additives:

Polymer compounds and additives in powder form are fed through a hopper and mixed to create the extrusion material.

2. Cooling of additives:

To prevent premature melting, the additives are cooled before being fed into the extruder. They are transported to a cooler and supplied continuously to the extruder.

3. Melting of plastic compounds:

The extruder’s screw gradually moves the materials along the barrel, and the generated heat melts the plastic compounds.

4. Temperature control:

External heaters are used to maintain the desired temperature as the melted plastic progresses through the barrel.

5. Shaping through a die:

Once the plastic is molten, it is directed through a die, which gives it the desired profile or shape.

6. Continuous process:

Plastic extrusion is a continuous process, allowing for high-volume output and making it a more practical manufacturing method compared to other processes. Plastic extrusion offers efficient production capabilities and is commonly used in various industries for creating profiles, pipes, tubes, and other plastic products. Its ability to handle high volumes and maintain consistent quality makes it a preferred choice in plastics manufacturing.